Process Ovens.

As well as Finishing Ovens and paint line finishing equipment, td finishing also offer a full range of process ovens for a wide range of manufacturing industries including, but not limited to, AMS Ovens, Military, Marine and Composites.

The processes catered for include low-temperature material & drum warming, pre-treatment and paint drying, as well as heat treatment and high-temperature coating cure. Front opening as well as top-loading oven dryer options are available with manual, powered or automated door systems.

td finishing ovens are available for AMS 2750E process and can be supplied in line with Furnace Class requirements 1 to 5 along with Instrument Types A to E, as indicated in the tables below;

| Furnace Class | Temperature Uniformity Range (°F) | Temperature Uniformity Range (°C) |

| 1 | ± 5 | ± 3 |

| 2 | ± 10 | ± 6 |

| 3 | ± 15 | ± 8 |

| 4 | ± 20 | ± 10 |

| 5 | ± 25 | ± 14 |

| 6 | ± 50 | ± 28 |

| Sensors Required by Instrument Type | Instrument Type | ||||

| A | B | C | D | E | |

| One control sensor per zone that controls and displays temperature | ✓ | ✓ | ✓ | ✓ | ✓ |

| The temperature indicated by the control sensor in each control zone shall be recorded by a recording instrument. Alternatively, the recording instrument may be connected to a second sensor contained in the same sheath or holder as the control sensor, and separated from the control sensor by no more than 10mm. | ✓ | ✓ | ✓ | ✓ | |

| At least two additional recording sensors in each control zone shall be located to best represent the coldest and hottest temperatures based on the results from the most recent temperature uniformity survey. | ✓ | ✓ | |||

| At least 1 recording sensor in each zone | ✓ | ✓ | |||

| Each control zone shall have over temperature protection. The recording sensor representing the hottest location may also be utilized as the over-temperature protection sensor. | ✓ | ✓ | ✓ | ✓ | |

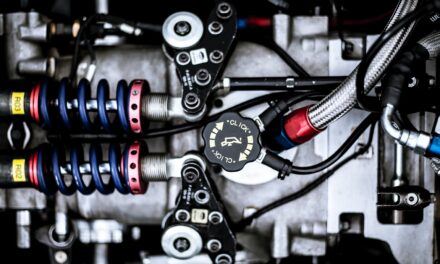

Where required process ovens can be supplied with multi-channel chart recorders, thermocouple & vacuum manifolds, process deviation alarms and touch screen HDMI systems with ethernet connection/ remote monitoring capabilities.

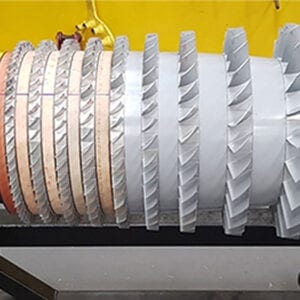

For continuous processes we offer a full range of overhead monorail conveyor systems and flat-bed conveyorized ovens. Fitted with efficient positive pressure air-knives and Electric-heater batteries or fully modulating (gas and air) burners.

So, if you have requirements for process ovens from drum warming to Aeroplane manufacture, don’t hesitate to contact us today.

You might also like to read our previous blog on powder coating system

All the latest Manufacturing News brought to you by AIM Internet.

AIM Internet specialise in digital marketing services that provide strategic online marketing solutions to grow your business. Contact us today to find out more.