The Power of Laser Cutting for Stainless Steel

Stainless steel is a material known for its strength, corrosion resistance, and versatility, making it a staple in various industries from automotive to construction. When it comes to fabricating stainless steel components with precision and efficiency, laser cutting is the method of choice. This blog delves into the specifics of laser cutting stainless steel, highlighting its advantages and applications, and why Stephens Gaskets is the go-to provider for stainless steel laser cutting services.

Why Stainless Steel?

Stainless steel is prized for its durability, resistance to corrosion, and aesthetic appeal. These properties make it an ideal material for components that require longevity and a clean finish, such as kitchen equipment, automotive parts, and architectural features. However, cutting stainless steel to precise specifications can be challenging due to its hardness and heat-resistant properties—this is where laser cutting excels.

Advantages of Laser Cutting Stainless Steel:

- Precision: Achieve clean, precise cuts with minimal burring or deformation.

- Efficiency: Laser cutting allows for fast production times, reducing lead times for projects.

- Versatility: Ideal for cutting both thin and thick sheets of stainless steel with equal accuracy.

How Stephens Gaskets Excels in Stainless Steel Laser Cutting

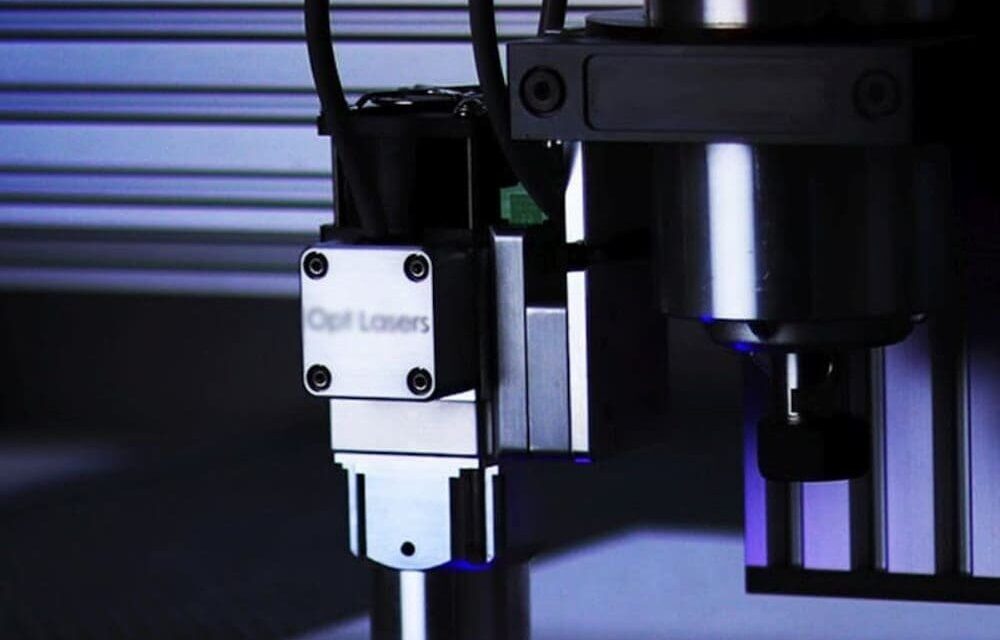

At Stephens Gaskets, we have honed our techniques to ensure that every stainless steel component is cut with the highest level of precision and quality. Our advanced laser cutting machinery allows us to handle a variety of stainless steel grades and thicknesses, ensuring that we can meet the specific requirements of your project.

Our Process:

- Material Selection: We work with various grades of stainless steel, each offering unique properties that can be leveraged depending on the application.

- Advanced Cutting Techniques: Our laser cutting machines use the latest technology to ensure clean cuts with minimal material wastage.

- Quality Control: Every piece is subjected to rigorous quality checks to ensure that it meets the highest standards of accuracy and finish.

Applications of Laser Cutting in Stainless Steel

Laser cutting is used to fabricate stainless steel components across a wide range of industries. Here’s a closer look at some of the key applications:

Automotive Industry:

Stainless steel is commonly used in automotive exhaust systems, brackets, and engine components. Laser cutting ensures that these parts are fabricated to the exact specifications needed for high-performance vehicles.

Architectural Features:

In architecture, stainless steel is used for decorative elements such as railings, panels, and cladding. Laser cutting allows for intricate designs to be realised with precision, contributing to the aesthetic appeal of modern buildings.

Kitchen Equipment:

Stainless steel’s resistance to corrosion makes it ideal for kitchen equipment such as countertops, sinks, and appliances. Laser cutting ensures that these items are fabricated with clean edges and a smooth finish, essential for both function and hygiene.

Conclusion: Partner with Stephens Gaskets for Stainless Steel Laser Cutting

Laser cutting is the preferred method for fabricating stainless steel components with precision and efficiency. At Stephens Gaskets, we combine advanced technology with expert craftsmanship to deliver high-quality stainless steel parts that meet the exact needs of our clients. Contact us today to learn more about our stainless steel laser cutting services and how we can help with your next project.

For more information on our comprehensive laser cutting services, visit our Laser Cutting Services page.

To read the original article please see here