When it comes to choosing the right gasket, it is likely you have found yourself faced with countless different options. All of which, are heavily promoted by gasket manufacturers as being the right one for the job. However, there are many different factors that can determine whether the gasket is right for your application. Some of which include:

- Size

- Corrosion Resistance

- Temperature Resistance

- Sealing Ability

- Water Resistance

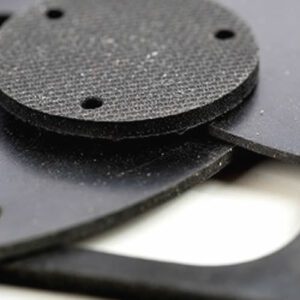

Gaskets are placed in between two surfaces to fill a gap. If two surfaces are not perfectly flush or straight, there can be room for movement. In addition, in some environments, there could be a channel for fluid or gas movement. Therefore, gaskets correct these gaps as they are compressed between the two surfaces. Consequently, eliminating any gaps and pathways for leakages.

When choosing the right gasket, you should first consider all of the details of the application environment such as:

- How uneven the surface is (this will help determine the thickness of the gasket).

- The gasket compressibility.

- Any contaminants the gasket will be exposed to.

How To Choose The Right Gasket Material

To choose a gasket material you need to consider looking at the environment the gasket will be used in. You need to take note of anything that the gasket may be exposed to. For instance, water, acid, alkalines, oxidation, oil or other harsh chemicals.

Metal gaskets, such as low carbon steel, and stainless steel gaskets work well in high-pressure applications. They are commonly used in the oil and gas industries and can provide great resistance to a number of different liquids and chemicals.

Whereas, non-metal gaskets are ideal for applications that require compression between two surfaces with little tension. With this in mind, they work well in systems where the fluid contents have low pressure levels. Additionally, they are unable to force a leak channel through the gasket. From graphite gasket to rubber gaskets and PTFE gaskets, at Stephens Gaskets we have plenty of different gasket materials to choose from.

Fluid Temperature, Corrosive Properties, and Pressure

If you choose a gasket that is not aligned to the application environment’s temperature, materials, or pressure, it is likely that they will fail at their performance. Every gasket’s material will have properties that make it specific for a range of fluid or ambient temperatures, pressures, and chemical exposures. For instance, silicone gaskets have a broader temperature range than neoprene gaskets. Non-metallic gaskets are usually only suitable for low pressure applications. Whereas, metallic gaskets are well suited for extremely high pressures.

Stephens Gaskets | Choose The Right Gasket

As one of the country’s leading suppliers of gaskets, here at Stephens Gaskets we can help you find the perfect gasket for your application. We have many different gasket materials to choose from. Therefore, no matter what properties you are requiring from the gasket, it’s highly likely that you’ll find a match with our components.

If you would support in choosing the right gasket, or you would like to find out more about our gasket materials, then please head to our website today. Alternatively, you can call 0121 544 5808 to speak to a member of our helpful and friendly team.

If you have found this blog helpful, then you may wish to read our previous blog on Using Stainless Spring Steel Strip For Washers.