Looking to invest in a finishing plant? Maybe you’re struggling with an ageing powder coating plant or paint finishing system, or perhaps you need a drying or curing oven replacement? People often overlook powder coating systems maintenance, upgrades, and replacements. However, these assets can be an unforeseen disaster for production when they do go wrong. Obsolete parts and long-lead times can lead to further woes when a suitable maintenance spares package has not been kept well stocked.

Efficient Service To Suit Your Needs

One of our clients made contact with TD Finishing to place an order for a replacement curing oven. The oven needed to be up and running within 4 weeks. This order is one that we consider quite tall. However, working from customers dimensioned sketches the equipment was designed, delivered, installed and running within the allotted time.

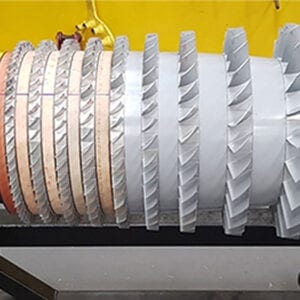

The curing oven was supplied with a much smaller, modern electrical control panel. This was compliant to the relevant standards. As highly efficient modulating gas & air burners, td’s negative-pressure air-seals were also supplied. The result, a completely upgraded, modernised powder curing oven.

It all ended well in this instance. However, most breakdowns and plant failures can turn into a huge headache for any size of business. If you fail to service and maintain burners and fans, a dip or spray pre-treatment system can have serious, long term financial consequences.

The Importance Of Finishing Plant Maintenance

There are many ways that a poorly maintained paint plant can effect your final product finish. For example, dirty tanks and blocked nozzles inside a spray pre-treatment system can often be hard to diagnose when the finishing plant is running. However, when the water quality in the tank degrades, the adhesion of paint or powder will be slowly heading towards failure. This may be in the form of rejected components or eventual failure in the field, under warranty. Anything from a day to months’ worth of production could be at risk due to poor maintenance and quality control.

Temperature Uniformity Survey

The results of unmaintained drying oven and curing oven burners are more obvious. Failing to monitor or regularly check an oven’s temperature uniformity, can lead to wet components entering the powder booth. It can also lead to uncured components leaving the curing oven. Heat cycling or replacement fans drastically alter temperature distribution. Therefore, it’s important to regularly carry out a Temperature Uniformity Survey (TUS. You can then make sure your ovens are running to the correct commissioned specification.

Wide Variety Of Equipment Available

So, if you have any concerns over ageing equipment, are looking for a replacement, or would just like to check your finishing plant performance & safety, then td can offer replacement or service and maintenance packages for any of the following;

- Dip Pretreatment

- Spray Pretreatment

- Drying Ovens

- Powder Coating Ovens

- Conveyor Systems

- Water demineralisation

Call Us Today | Powder Coating & Finishing Plant Replacement

If you would like to find out more please visit our paint plant spares and service page. Alternatively, you can call or email us today to discuss your paint finishing plant replacement requirements. One of our team will be happy to help whatever the query on 0121 520 8884 or email info@tdfinishing.co.uk.

If you enjoyed reading this article you may also like to read our previous blog post: Conveyorised Powder Coating Systems – Power & Free