Two-Pack Epoxy Primer Finish

This high-performance coating for the rail industry is an epoxy air-drying solvent-based coating, with low VOC content, specially developed as a single coat application, or multi coat system for application to a wide range of substrates. RWIP120 is part of a family of coatings manufactured from a high grade two-part epoxy system initially procured for use in aerospace applications and developed for use within the rail industry on underframe components, including wheelsets, bogies, air reservoirs and motors (new and refurbished) and heavy engineering.

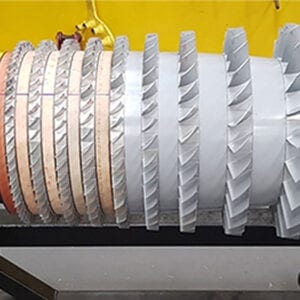

Typical application of RWIP120 on wheel set

RWIP120‘s performance covers a long list of rail industry challenges. Including impact, chip and scratch resistance and the ability to withstand high humidity. Alongside resistance to abrasion, salt spray and wash plant operations.

The cured coating provides excellent corrosion protection on steel, aluminium and galvanized substrates, as well as in immersed conditions. It is a tough, chemically resilient finish that has been tested against a variety of corporate and national standards. The coating performs in temperatures ranging from +200 ºC. down to -50 ºC and can also be applied directly to GRP and composite substrates.

Air Reservoir Before Application of IPRW120

Typical application of RWIP120 on Air Reservoir

Applied as a single or two coat application, by airless spray, conventional spray, or brush / roller, and can be overcoated with itself or other Indestructible Paint finishes, epoxy’s and polyurethanes.

Product is available as a Matt, Semi-Matt, Semi-Gloss and full gloss finish, in a limited range of BS and RAL colours.

The coating is supplied as a two-component product, mixed 3:1 part by volume with standard catalyst and the mixed material will remain stable for 4 hours. Supplied as a 4 litre or 20 litre kit including catalyst.

Typical application of RWIP120 on bogie

If you would like to find out more about this and other protective coatings for rail vehicles and for Safety Data Sheets on any of the products mentioned, call +44(0)121 702 2485 to speak to a member of our helpful and friendly sales team.