In today’s competitive manufacturing landscape, the quest for efficiency and quality is relentless. At Stephens Plastics, we understand that the cornerstone of success lies in the ability to merge these two critical factors seamlessly. Through our advanced moulding services, we’ve set a benchmark in the industry, ensuring that efficiency and quality are not mutually exclusive but complementary. This blog post explores our insights and methodologies that have propelled us and our partners to the forefront of the manufacturing sector.

The Foundation of Efficiency and Quality

Embracing Technological Innovation

Innovation is at the heart of maximising efficiency. At Stephens Plastics, our investment in cutting-edge technologies and machinery underpins our entire operation. From automated injection moulding processes to real-time monitoring systems, we leverage technology to streamline production, reduce waste, and increase output, all while maintaining the highest standards of quality.

Precision Engineering for Unmatched Quality

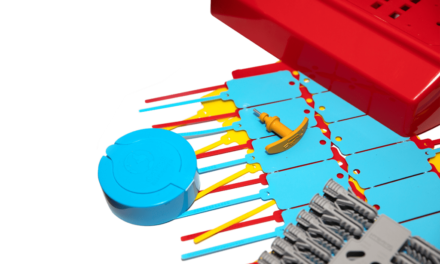

Quality is a hallmark of Stephens Plastics. Our precision engineering capabilities allow us to produce components with exacting tolerances and superior finishes. This meticulous attention to detail ensures that every product we manufacture meets rigorous quality standards, satisfying the most demanding specifications of our clients.

Strategies for Enhancing Efficiency and Quality

Lean Manufacturing Principles

Adopting lean manufacturing principles has been pivotal in our approach to maximising efficiency. By continually analysing and optimising our processes, we eliminate waste and reduce lead times. This lean approach not only boosts our operational efficiency but also enhances product quality by minimising opportunities for defects.

Continuous Improvement Culture

At Stephens Plastics, the drive for improvement is never-ending. Our culture of continuous improvement encourages innovation, collaboration, and problem-solving at all levels of the organisation. By fostering this culture, we remain agile, adapting to new challenges and opportunities to further enhance efficiency and quality.

Leading Through Expertise and Collaboration

Industry Leadership with Advanced Moulding Services

Our advanced moulding services have positioned Stephens Plastics as an industry leader. By offering comprehensive solutions, from design and prototyping to mass production and post-production analysis, we provide a one-stop-shop for our clients. This integrated approach not only ensures efficiency and quality but also simplifies the supply chain, providing a more streamlined and reliable manufacturing process.

Partnership and Collaboration for Success

We believe that true success is achieved through partnership and collaboration. By working closely with our clients, suppliers, and industry experts, we gain insights that drive innovation and improvement. These collaborations allow us to stay ahead of industry trends, anticipate future challenges, and continuously deliver products that set new standards in efficiency and quality.

Conclusion

At Stephens Plastics, maximising efficiency and quality through advanced moulding services is more than just an operational goal – it’s a commitment to excellence and innovation. Our insights and strategies in these areas have not only enhanced our capabilities but have also provided tangible benefits to our partners across various industries.

For businesses seeking a manufacturing partner that prioritises both efficiency and quality, Stephens Plastics offers the expertise, technology, and collaborative approach needed to succeed in today’s market. Join us as we continue to push the boundaries of what’s possible in manufacturing, creating value and driving standards across the industry.

To read the original article please see here