THE CHALLENGE: For nearly 100 years MacLean-Fogg has helped provide innovative products for North America’s railroads and beyond. Their Buffalo, New York manufacturing operation currently produces key components for the automotive industry.

The continuous improvement team identified that they needed to transform their paper-based process into something that was better organised, offering more clarity and accountability. This in effect would improve their overall performance.

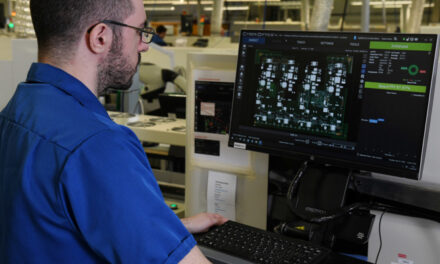

THE SOLUTION: NoMuda VisualFactory was used to create guided processes to take the place of paper instructions.

It quickly became the standard process at each of the crucial cells on the floor. The guided processes give live reaction plans to operator inputs, provide valuable production data, and are compatible with industry 4.0 functionalities.

The operator’s gauges have wireless transmitters to send part dimensions at the push of a button. VisualFactory reads the input and gives them the reaction plan shown on the next page. If the measurement is within tolerance, it will appear green and say that no stop and fix is required. If not, it will appear red and display the exact station, axes, direction, and distance to move the tool and bring the feature back to nominal.

The MacLean-Fogg Engineered Solutions team have found VisualFactory to be highly adaptable software that can be changed depending on the process requirements. The right process produces the right results, leading to improved results at MacLean-Fogg Buffalo.

“VisualFactory clarifies the production process and helps ensure the processes are executed correctly. Standard work is the foundation of continuous improvement.

As I worked with team members to document processes in the shop, we rarely got it right the first time. With VisualFactory, we quickly iterated our improvements to a better process.”

Ken Carmichael

Director of Continuous Improvement

THE BENEFITS:

- NoMuda VisualFactory was a major contributor to achieving a 68% increase in Operating Profit with 30% fewer sales in 2021.

- MacLean-Fogg are enjoying stable quality, productivity, and delivery results.

- NoMuda VisualFactory has improved results by supporting people and processes through greater clarity and accountability.

- MacLean-Fogg has experienced fewer tool setting errors and have prevented machine-damaging crashes. They have reduced the need for engineering support on VisualFactory processes by more than 90%.

- Trainees go from novice to mastery much faster, with operator morale improving as a result. They can then achieve process mastery to autonomy much sooner.

Learn how you can achieve real cost savings with NoMuda VisualFactory at www.NoMuda.com

To read the original article please click here: https://www.mtdmfg.com/news/nomuda-visualfactory-helps-maclean-fogg-increase-operating-profit-by-68-2/