Wet Working

Working in the wet is one of the most hazardous environments, with slipping being the most common cause of injury. But if you cannot avoid walking on a wet surface, slow down and take smaller steps. This will help you keep your balance and avoid slipping or falling. However, working in an environment where the floor is constantly washed down, it is recommended to resurface all pedestrian areas with a material that provides a low slip-risk (hygienic food grade flooring).

The Right Product For The Job

The product of choice for a hygienic food grade flooring in the food industry and wet production is a Resdev Pumadur RT. This is resin-rich, heavy duty and trowel applied polyurethane floor screed. It can be used on concrete and polymer modified cementitious screeds. In particular Resdev Pumadur RT is designed to give the floor durability, as well as impact, abrasion and chemical resistance. Moreover, the lightly textured finish makes the product ideal for both wet and dry processing environments. For instance, the food, beverage, and chemical industries.

Case In Point

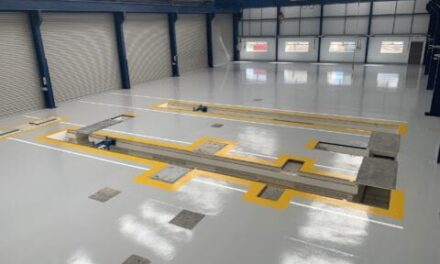

PSC were recently called in to look at refurbishing floor area to Fish Processing Area totalling 53 square metres. Robert Miller Ltd has supplied both fresh and frozen fish for over 30 years in and around Essex to restaurants and customers. At their fish processing plant in West Hanningfield, Essex, the existing laytex, resin coats and localised failed floor screed was beyond repair. It was recommended that the area would benefit from complete refurbishment. Laying a new nominal 6mm Resdev RT polyurethane screed – the hygienic food grade flooring product of choice.

In preparation for the 6mm screed, the laytex, resin coats and localised failed floor screed were all removed. The existing concrete floor surface keyed, using a handheld 110v PCD grinding machine and a handheld total enclosed 110v diamond grinding machine. Subsequently, the area was vacuumed clean of all residues.

In order to ensure a clean edge, 6mm x 6mm saw cuts were made to the perimeter of floor area. This included door thresholds, around drains and gullies and where necessary to toe in and anchor the screed. After that, a nominal 6mm heavy duty Resedv Pumadur RT polyurethane, textured, matt, in the clients Chelsea Blue was laid to the entire area.

The client commented “A complete transformation of a very busy area. The area is an integral part of the processing plant and hence is in constant use. The floor has gone beyond repair and hence required complete refurbishment. PSC have completely transformed the area, on budget and within the timescale we set”. The entire job was completed in just 2 days. 1 day to prepare the floor and a further day to install the 6mm RT resin screed.

Safe and Hygienic Food Grade Flooring | Call us Today

If you would like to find out more about safe and hygienic food grade flooring, then head to our website today or call a member of our experienced team on 01562 702047 to find out how we can help.

All the latest Manufacturing News brought to you by AIM Internet.

AIM Internet specialise in digital marketing services that provide strategic online marketing solutions to grow your business. Contact us today to find out more.